SK Siltron CSS Announces $300 Million Expansion in Bay County

July 14, 2021 4:48PM EDT

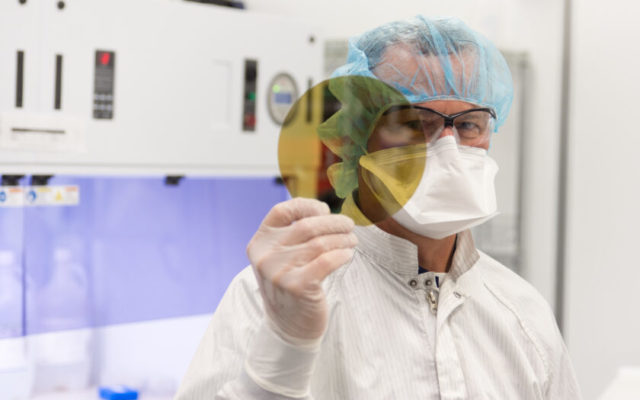

A scientist at SK Siltron CSS holds a silicon carbide wafer produced at the company’s Michigan facility. The company plans to expand its Michigan operations to increase production of these wafers, which can be used in power system components for electric vehicles. (source: SK Siltron CSS)